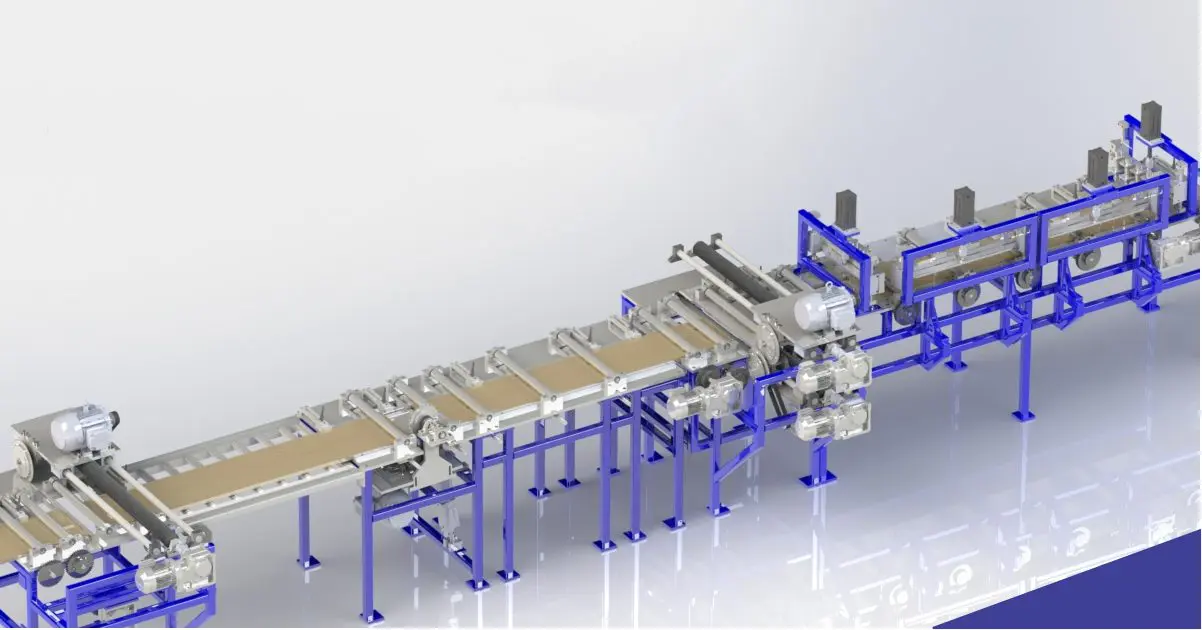

Special Purpose Machines (SPM)

Special Purpose Machines (SPMs) are advanced mechanical devices designed and built for specific industrial applications. These machines offer unparalleled precision, automation, and efficiency, enabling businesses to optimize their manufacturing processes and achieve higher productivity. By tailoring the design and functionality to meet unique production requirements, SPMs have become invaluable assets across a wide range of industries, from automotive and aerospace to electronics and pharmaceuticals. This article explores the features, benefits, and applications of special purpose machines, highlighting their significant contributions to modern manufacturing.

Features and Functionality:

Special Purpose Machines are meticulously engineered to perform a single, well-defined task or a set of closely related operations. They are designed with a specific purpose in mind, utilizing specialized components, control systems, and programming to accomplish their intended function. Some common features of SPMs include:

Customization: SPMs can be tailored to suit the precise needs of a particular manufacturing process, ensuring optimal performance and output.

Automation: These machines incorporate sophisticated control systems, such as programmable logic controllers (PLCs) or computer numerical control (CNC), enabling autonomous operation and reducing the need for manual intervention.

Precision: SPMs are built with high-precision components, allowing them to achieve tight tolerances and deliver accurate results consistently.

Integration: SPMs can seamlessly integrate with other manufacturing systems, such as conveyor belts, robotic arms, or vision systems, enhancing the overall efficiency and productivity of the production line.

Benefits of Special Purpose Machines:

The utilization of Special Purpose Machines provides numerous benefits to industrial operations, including:

Increased Productivity: By automating repetitive or complex tasks, SPMs significantly boost production rates, enabling businesses to manufacture more products in less time.

Improved Quality Control: With their high precision and consistency, SPMs ensure product uniformity, reducing errors and defects. This leads to higher-quality end products and increased customer satisfaction.

Cost Efficiency: SPMs optimize resource utilization by minimizing material waste and reducing labor requirements. This results in cost savings and improved profitability for businesses.

Enhanced Safety: SPMs can be equipped with advanced safety features, such as sensors, emergency stops, and interlocks, ensuring a safe working environment for operators.

At InnoSewa, we believe that valuable, relevant, and high-quality content is the foundation of successful communication and brand building. Our dedicated team of skilled writers is passionate about creating content that captivates, educates, and drives results. Partner with us to unlock the power of compelling content

Applications of Special Purpose Machines:

Special Purpose Machines find applications in a wide range of industries, including:

Automotive Manufacturing: SPMs are used for operations like assembly, welding, painting, and inspection in automobile production lines, increasing efficiency and maintaining quality standards.

Electronics Manufacturing: SPMs play a crucial role in the production of electronic components, such as circuit boards, semiconductors, and consumer electronics, ensuring precise placement, soldering, and testing.

Packaging Industry: SPMs are employed for tasks like filling, sealing, labeling, and packaging of various products, enhancing speed, accuracy, and consistency in packaging processes.

Pharmaceutical Industry: SPMs facilitate precise dosage filling, blister packaging, labeling, and inspection of pharmaceutical products, ensuring compliance with stringent quality standards.

Aerospace Industry: SPMs are utilized for complex operations like drilling, milling, and assembly of aircraft components, ensuring precision and adherence to aerospace engineering specifications.

We help you to see world differently , discover oppurtunities you may never have imagined.